The Philippine Center for Postharvest Development and Mechanization (PhilMech) has successfully developed a mango sorting machine that enables farmers to cut production costs and increase product value.

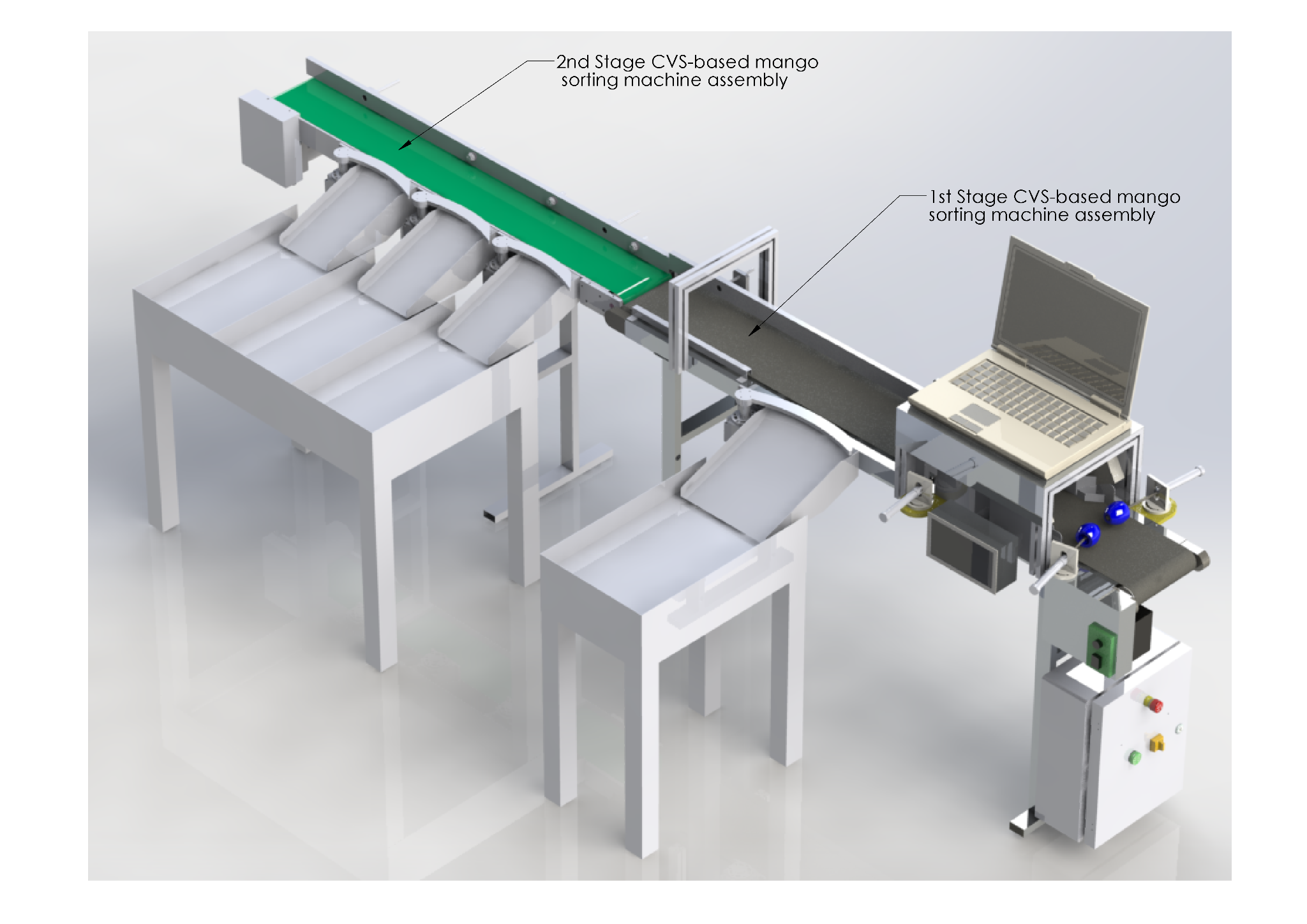

The PhilMech automated mango sorting machine uses a computer vision system to sort and classify green mango fruit. The machine can detect external defects, weight, and sizes. It works by feeding the mango fruits into the machine through a conveyor belt and passing through an imaging chamber before being sorted directly into the classification bins. Use of the machine will cut the labor requirements from 20 workers down to two workers.

The machine was able to record a 94.44% accuracy and precision in sorting and grading mango fruits following international standards for exports. It can also process up to 720 to 800 pieces of mango per hour.

PhilMech expects that the sorting machine will be available to farmers at an affordable price. Compared to similar imported products, which may cost up to P1 Million, producing a unit of PhilMech mango sorting machine only costs around P168,000.

Tackling the concern of unemployment due to the automation of industries, lead developer Engineer Arlene Joaquin expresses that the Automated Mango Sorting Machine can be seen as an opportunity rather than a threat. She shared that among the concerns of some mango farms is the lack of manpower especially during peak harvest season.

“Ang isa pong problema sa industry ay yung kapag nagsabay-sabay yung harvest, wala pong makuhang tao. And, [the Mango Sorting Machine] is a very good intervention kasi kumukuha pa po sila ng mga laborers sa neighbotowns,” said Engr. Joaquin.

The PhilMech expectsto develop the machine further to cater to export-intended mangoes and other products. “Next year, naka-programa itong subukan in the export of mangoes. So, exporters po ang titingin nito based on actual capacity and also for other circular vegetables,” said Engr. Joaquin.

NSAARRD 2023

This PhilMech research project, “Automated Mango Sorting System,” placed 2nd runner-up under the Research Category at the 2023 National Symposium on Agriculture, Aquatic, and Natural Resource Research and Development (NSAARRD). Led by the Philippine Council for Agriculture, Aquatic and Natural Resource Research and Development of the Department of Science Technology (DOST-PCAARRD), NSAARRD showcases the most outstanding contributions of individuals and institutions in the field of AANR research and development.